Paperboard is more than just a material—it’s the foundation for the high-performance, high-impact packaging we deliver across industries!

As leaders in the custom packaging space our clients rely on paperboard to bring structure, sustainability, and style to their custom packaging solutions. From cosmetics to consumer goods, we’ve been helping to bring clients’ visions to life using paperboard since 1981.

Our experiences have taught us that choosing the right type of paperboard is a critical step in the design and production process. It impacts everything–from durability and shelf presence to sustainability and cost-efficiency.

As consumer preferences shift toward recyclable, renewable materials and premium unboxing experiences, paperboard gives brands the flexibility to evolve without compromise.

If you’re new to packaged goods, this guide will teach you everything you should know about how to choose the right paperboard for your business or brand.

Next, we’ll walk through the most common types of paperboard we use, their treatments and finishes, and the industries they serve.

Table of contents

- What is paperboard and why it matters for custom packaging

- The major types of paperboard

- Popular surface treatments and finishes

- How industries use paperboard in packaging

- Paperboard selection and environmental considerations

- Why customers keep choosing paperboard

What is paperboard and why it matters for custom packaging

Paperboard is a thick, paper-based substrate made from cellulose fibers, engineered to be both strong and lightweight. Compared to traditional paper, it offers more rigidity and structural integrity, making it suitable for packaging applications that need to stand up, hold shape, and protect contents.

In custom packaging, paperboard is especially valuable because it strikes a balance between performance and presentation. It can be printed, embossed, foil-stamped, die-cut, and coated—allowing us at Spectrum to design packaging that meets specific product requirements while creating a memorable brand experience.

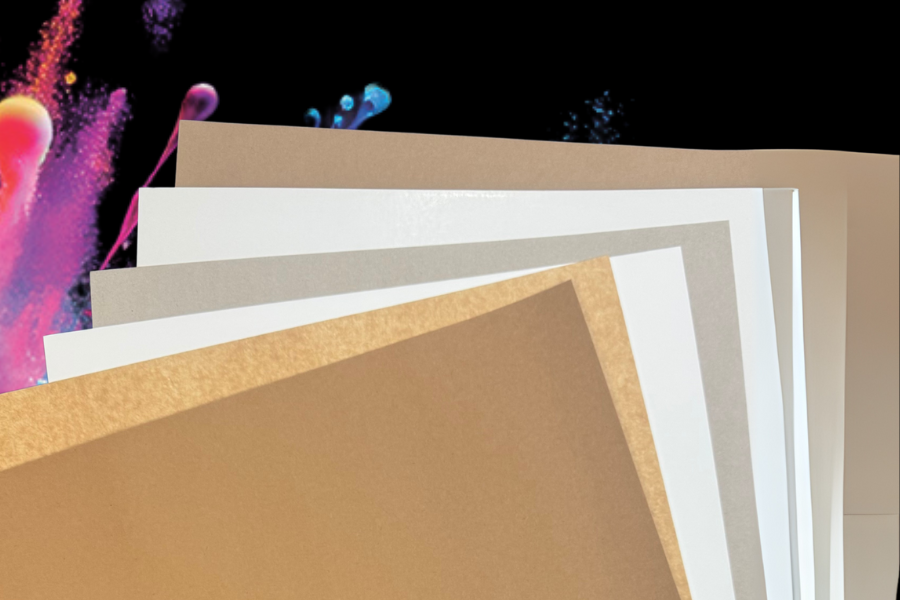

The major types of paperboard

At Spectrum, we work closely with our customers to select the right board based on performance needs, aesthetic goals, and budget. Here are the most commonly used types of paperboard in our custom packaging projects:

Solid Bleached Sulfate (SBS)

Solid bleached sulfate is a premium-grade paperboard made from 100% virgin fiber and bleached for a bright white appearance on both sides.

We frequently use solid bleached sulfate paperboard for:

- Luxury cosmetic packaging

- Premium folding cartons

- Health & wellness products

In instances where visual quality and product protection are our clients’ top priority, we can recommend solid bleached sulfate paperboard.

Coated Unbleached Kraft (CUK)

Coated unbleached kraft, sometimes referred to as solid unbleached sulfate (SUS), is a durable kraft-based paperboard with a natural brown back and a coated white front.

CUK is engineered for strength and moisture resistance, which makes it ideal for:

- Beverage packaging

- Frozen food cartons

- Greasy or oily foods

Because of its toughness and moisture resistance, coated unbleached kraft paperboard is widely used in beverage carriers and other high-stress packaging environments.

Coated Recycled Board (CRB)

Coated recycled board is made primarily from recycled fibers and has a clay-coated surface for improved print performance.

Coated recycled board is a cost-effective and sustainable option widely used in packaging for:

- Dry goods

- Household items

- Personal care products

This balance of sustainability, affordability, and print quality makes CRB an attractive solution for brands looking to reduce environmental impact while maintaining shelf presence.

Folding Box Board (FBB)

Folding box board is a multilayered board commonly used in Europe and gaining popularity in North America.

Folding box board combines mechanical and chemical pulps to create a board that is lightweight yet stiff, and has good print properties. It’s often used in:

- Personal care items and toiletries

- Over-the-counter pharmaceuticals

- Tobacco products (Europe)

- Toys and small appliances

FBB provides impact without the bulk. With its unique balance of lightweight strength, cost efficiency, and premium printability, it stands out as a versatile solution for brands seeking both visual impact and practical performance across a wide range of consumer goods.

White Lined Chipboard (WLC)

White lined chipboard, also made from recycled fibers, features a white top liner and a gray or brown reverse side.

WLC is commonly used in secondary packaging and cost-sensitive retail applications:

- Dry & ambient food packaging

- Frozen & refrigerated foods

- Household products with high recyclability appeal

WLC is recycled, cost-effective, and print-friendly. This makes it a strong choice for mass-market consumer packaging where premium appearance is less critical than sustainability and affordability.

Popular surface treatments and finishes

The finish applied to paperboard packaging can transform it from a simple container into a powerful brand statement. Surface treatments not only protect the package but also shape how consumers perceive and interact with it.

Clay coating

Clay coating provides a smooth, even surface that’s perfect for high-quality offset printing. This treatment ensures sharp text, vibrant colors, and detailed images — essential for brands competing for attention on crowded shelves.

UV and aqueous coating

To further enhance visuals, UV and aqueous coatings are commonly applied. UV coatings create a striking high-gloss effect with bold contrast, while aqueous coatings offer more versatility, from glossy to matte to satin. Both add durability by reducing scuffs and fingerprints, ensuring packaging maintains its premium look.

Soft touch lamination

For products where touch is as important as sight, soft touch lamination delivers a velvety, tactile surface that elevates the unboxing experience. This finish is especially popular in cosmetics, luxury goods, and specialty foods, where subtle sensory cues help communicate quality.

Foil stamping and embossing

Brands aiming for visual drama often turn to foil stamping and embossing. Metallic foils reflect light and add brilliance, while embossing creates raised textures that engage the sense of touch. Together, these techniques highlight logos, borders, and other design elements that signal exclusivity.

Functional coatings

Finally, some packaging requires performance over polish. Functional coatings, such as grease- and moisture-resistant layers, protect against oils, sauces, and condensation. These finishes are especially valuable in food service, refrigerated, and frozen food applications where durability and safety are just as critical as appearance.

Surface treatments and finishes go beyond decoration — they shape how consumers see, feel, and trust a package. From boosting shelf appeal to adding protection, the right finish ensures packaging works as both a protector and a brand ambassador.

How industries use paperboard in packaging

Paperboard’s versatility makes it a foundation for packaging across a wide range of industries. Its balance of strength, printability, and adaptability allows brands to tailor solutions that meet both functional demands and consumer expectations.

Food & beverage

Paperboard is widely used for dry goods, frozen meals, and beverage carriers. Boards such as CUK and CRB offer the strength and resistance needed for heavier loads and refrigerated environments, especially when paired with food-safe coatings that guard against grease and moisture.

Cosmetics & Pharmaceuticals

For industries where trust and appearance are paramount, boards like SBS and FBB deliver a clean, bright surface that supports detailed printing and premium finishes. This ensures packaging not only protects the product but also reinforces brand identity through visual quality.

Retail & consumer goods

Electronics, toys, and household items often require packaging that balances protection with presentation. Paperboard excels here, offering custom cartons, sleeves, and display-ready formats that align with branding while keeping products safe during handling and transit

E-commerce & subscription boxes

With the growth of direct-to-consumer shipping, paperboard has become essential for inserts, dividers, and die-cut solutions that keep items secure in transit. Beyond protection, these designs elevate the unboxing experience, turning packaging into a touchpoint that connects consumers with the brand.

Paperboard selection and environmental considerations

One of the biggest advantages of paperboard is its alignment with sustainability goals.

We regularly help clients meet their environmental goals by guiding them toward fiber-based solutions that are:

Recyclable

Most paperboard grades can be recycled through standard curbside programs, making them one of the most accessible sustainable packaging options for both brands and consumers.

Responsibly sourced

Working with mills that carry FSC® or SFI® certifications ensures materials come from forests managed with ecological, social, and economic responsibility in mind.

Recycled content

Grades such as CRB and WLC include post-consumer recycled fiber, reducing reliance on virgin pulp and supporting a more circular fiber economy.

Lighter carbon footprint

Compared to plastics or rigid alternatives, paperboard typically weighs less and occupies less volume during shipping. These efficiencies lower transportation emissions and contribute to a smaller overall footprint.

It’s important to note that some finishes—like plastic lamination or foil—can complicate recycling. That’s why our packaging experts work with clients to balance design intent with end-of-life outcomes, creating packaging that performs effectively while supporting long-term sustainability goals.

Why customers keep choosing paperboard

Paperboard continues to be a cornerstone of custom packaging thanks to its combination of versatility, quality, and sustainability.

We tailor every solution to your brand’s unique requirements—starting with the right board, the right finish, and a design that delivers on every level!

Looking to elevate your packaging with paperboard? Let’s explore which paperboard is right for your next project.